Comparative Study of SAE 8620 and EN 36C in an Automotive Differential

Summary

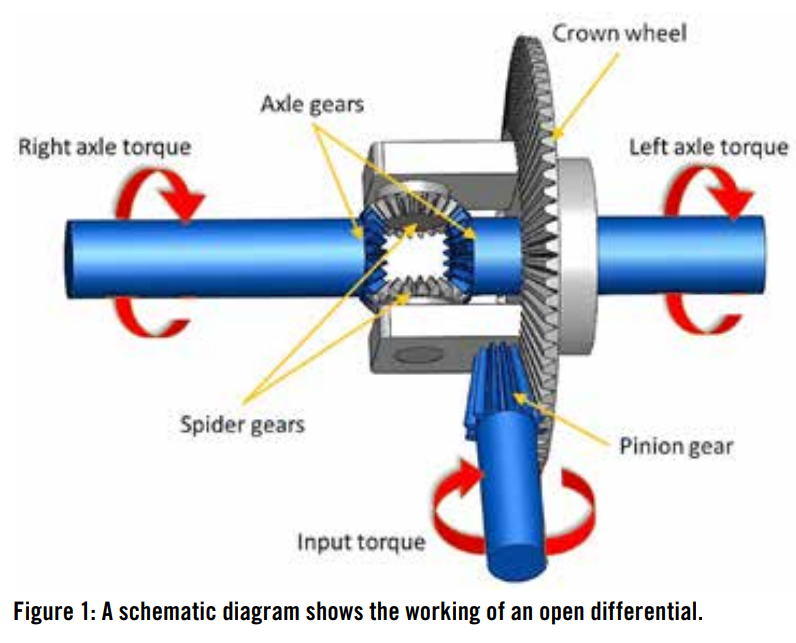

This research provides a comprehensive comparison of two case hardening alloy steels, SAE 8620 and EN 36C, in the context of their application in automotive differential gearboxes. The study aims to evaluate and contrast these materials based on various performance metrics crucial for automotive applications.

Research Highlights

- Objective: Design and analyze differential gearboxes using SAE 8620 and EN 36C to determine the most suitable material for specific automotive uses.

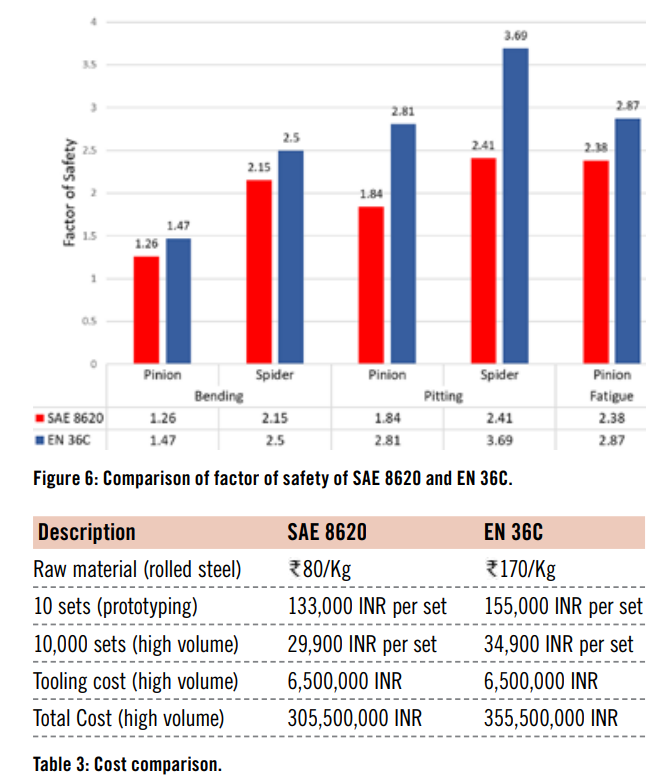

- Findings: The study revealed that EN 36C exhibits significantly better tooth strength, wear resistance, and fatigue properties compared to SAE 8620.

- Cost-Effectiveness: While SAE 8620 shows satisfactory performance, it stands out for its cost-effectiveness, making it suitable for high-volume production scenarios.

- Material Selection Insight: The research offers valuable insights for material selection in the context of automotive gear manufacturing, highlighting the trade-offs between performance and cost.

Conclusion

This comparative study brings forth critical data and insights about SAE 8620 and EN 36C steels, assisting manufacturers and engineers in making informed decisions about material selection for automotive differentials. The balance between performance attributes and economic factors plays a pivotal role in these decisions.

Full article available in Gear Solutions Magazine.

Authors: Saurav Kambil and Ankur Miglani

Institution: Indian Institute of Technology Indore

Publication: Gear Solutions Magazine

Focus: Comparative analysis of materials in automotive differential gearboxes